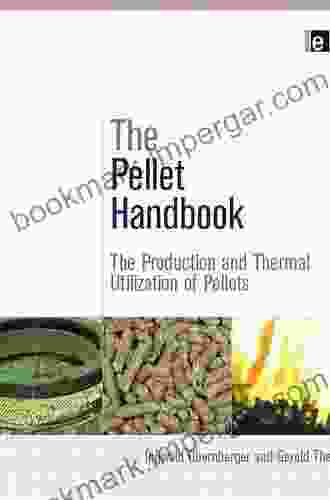

In the pursuit of sustainable energy solutions, biomass pellets have emerged as a promising alternative to traditional fossil fuels. Made from compressed organic matter such as wood, agricultural residues, and other plant-based materials, biomass pellets offer a cleaner, more efficient, and environmentally friendly way to heat homes, businesses, and industries.

5 out of 5

| Language | : | English |

| File size | : | 10740 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 593 pages |

This comprehensive guide delves into the production process of biomass pellets, exploring their properties, advantages, and applications in thermal utilization systems. With a focus on sustainable practices and energy efficiency, we aim to provide a deeper understanding of this renewable energy source and its transformative potential.

Production of Biomass Pellets

The production of biomass pellets involves several key steps:

Raw Material Collection

Biomass pellets can be made from various types of organic materials, including:

- Wood chips and sawdust - Agricultural residues like straw, corn stalks, and sugarcane bagasse - Forest and mill residues - Energy crops grown specifically for pellet production

Grinding and Drying

The collected raw material is first ground into smaller pieces to facilitate further processing. It is then dried to reduce moisture content, which improves the pellet's durability and energy density.

Pelleting

The dried biomass is then fed into a pellet mill, where it is compressed under high pressure and temperature. The resulting pellets are cylindrical or cubic in shape, with a diameter typically ranging from 6 to 12 millimeters.

Cooling and Packaging

The hot pellets are cooled and screened to remove any fines or dust. They are then packed into bags or bulk containers for storage and distribution.

Properties and Advantages of Biomass Pellets

Biomass pellets possess several unique properties that make them an attractive fuel source:

High Energy Density

Biomass pellets have a higher energy density compared to loose biomass, making them more efficient to store and transport. Their compact form allows for convenient handling and utilization in various applications.

Low Emissions

When burned properly, biomass pellets release significantly lower levels of harmful emissions, such as nitrogen oxides, sulfur oxides, and particulate matter, compared to fossil fuels. This contributes to improved air quality and reduces environmental impact.

Renewable and Sustainable

Biomass pellets are derived from renewable plant-based materials, making them a sustainable energy source. Their production and use can help reduce greenhouse gas emissions and promote responsible forest management practices.

Versatile Applications

Biomass pellets are primarily used for thermal applications, including:

- Residential heating in pellet stoves and boilers - Industrial heating and power generation - Commercial heating and cooking

Thermal Utilization of Biomass Pellets

Biomass pellets offer significant advantages in thermal utilization systems:

Efficient Combustion

Biomass pellets burn cleanly and efficiently, releasing heat with high calorific value. This efficient combustion process minimizes energy waste and maximizes heat output.

Automated Operation

Pellet stoves and boilers are typically automated, making them easy to operate and maintain. They can be programmed to maintain desired temperatures and provide consistent heat output.

Convenience and Comfort

Biomass pellets provide a convenient and comfortable heating solution. They require minimal handling and can be stored indoors, eliminating the need for outdoor storage of bulky fuels like firewood.

Environmental Benefits

The use of biomass pellets in thermal applications contributes to a reduction in carbon footprint. They emit fewer greenhouse gases than fossil fuels, fostering a more sustainable energy system.

Industry Advancements and Innovations

The biomass pellet industry is constantly evolving, with ongoing advancements and innovations:

Improved Pellet Quality

Research and development efforts are focused on enhancing pellet quality, including increasing energy density, reducing moisture content, and developing pellets with tailored properties for specific applications.

Efficient Pellet Production

Technological advancements aim to improve the efficiency of pellet production processes, reducing energy consumption and optimizing raw material utilization.

Advanced Combustion Systems

Innovation in pellet combustion systems focuses on maximizing heat output, reducing emissions, and improving overall performance.

Biomass pellets represent a promising renewable energy source with a wide range of applications in thermal utilization systems. Their high energy density, low emissions, sustainability, and convenience make them an attractive choice for reducing reliance on fossil fuels and promoting a greener future. As the industry continues to advance and innovate, biomass pellets poised to play an increasingly significant role in meeting our energy needs while safeguarding the environment.

By embracing the potential of biomass pellets, we can unlock a sustainable and efficient path towards a cleaner, healthier, and more energy-secure future.